Draw & Buffing Gear

Draw Gear:

It is a vital component of rolling stock, which is utilized to connect one rolling stock to the adjacent rolling stock to form a train & also to transmit draft forces from engine to last vehicle. It is provided in the centre of the body in the under frame head stock at both the ends. Mainly two types of draft gear are being utilized in Indian Railways.

Conventional Draft Gear and Centre Buffer Coupler

Main components of conventional draw gear:

Draft Hook Draft Links Draft Key

Draft Spring/ Draft Pad. Cotter Washer

Bent Pin (U-Pin) Hexagonal Nut Screw Coupling

Parts of Screw Coupling.

1. Link

2. Bent coupling link

3. Screw

4. Bent coupling

5. Lever 6. Trunnion

7. Trunnion

8. Snap head rivet dia 8 x 85

9. Pin 60 x 218

10. Collar

11. Snap head rivet 12 x 95

12. Collar

13. Snap head rivet 6 x 70

In 1984 use of Enhanced Screw Coupling was started, which was again modified in 1998. To identify this coupling a Dumble mark is stenciled at both the side of coach end body.

Length of coupling when fully opened – 997 mm

Length of coupling when fully Tight – 751 mm

Modifications:

Note: *Proof Load Capacity of Enhanced Screw Coupling is increased from 70T to 75T. This must be used in all coaches including 24 coach trains.

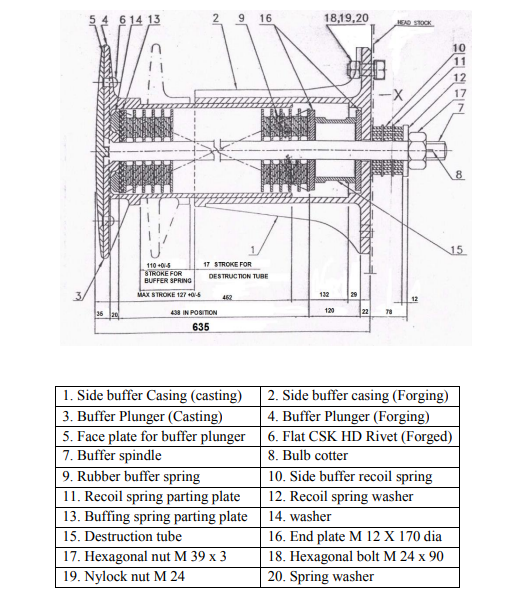

BUFFING GEAR:

Two nos. of buffers are provided on body head stock on both ends to absorb the longitudinal impacts during run, these are fitted at adistance of 1956 mm. The buffers also transmit buffing forces during pushing to its trailing end stock

The main components of Buffing Gear are as under:-

1. Buffer Plunger

2. Buffer Socket with securing bolt

3. Buffer Spindle & Plug

4. Buffing Pad

5. Destruction Tube

6. Recoil rubber Washer

7. Washer

8. Nut & Cotter

Mainly Buffers are of two types:-

Long Case Buffer – Length from head stock – 635 mm

Short Case Buffer – Length from head stock – 458 mm (4 wheeler)

Other data:

Max. Height in Empty condition – 1105 mm

Min. Height in Loaded condition – 1030 mm

Minimum buffer height of coaching stock should not be less than 1090 mm at the time of releasing of coach from POH Workshop.

Allowed variation in height at same end – 64 mm

Allowed variation with adjacent vehicle – 75 mm

Max. Plunger Travel – 127 mm

Min. Plunger Travel – 51 mm

No. Of Buffing Pads per Buffer – 14 to 16 Nos.

Capacity of Buffing Pads – 1030 kgm

2.4 Brake Rigging Brake rigging is provided for transferring the braking force from the brake cylinder to the wheel tread. Brake rigging is different for Bogie mounted brake system and under frame mounted brake system.

Coach under Frame Mounted Brake Rigging:

In 16.25 t axle load bogie the four levers used in bogie brake rigging are each with lever ratio of 1:1.376 hence the total Mechanical advantage in a bogie is 5.504.

In 13 t axle load bogie the four levers used in bogie brake rigging are each with lever ratio of 1:1 hence the total Mechanical advantage in a bogie is 4.

Bogie Mounted Brake Rigging:

The following parts are used in the Brake Rigging.

Lever- Straight, Lever- Z shaped, Lever Hanger, Connecting Link.

Bogie brake rigging has been modified to incorporate a total mechanical advantage of 7.644 per bogie for Non-AC coaches and 8.40 per bogie for AC coaches

Brake rigging of BMBS is discussed in detail in the BMBS chapter

No comments:

Post a Comment