RIDING INDEX

The assumptions for the formulation of certain standards of assessing comfort is purely from the point of view of vehicle oscillations transmitted to passengers only. The human sensation of comfort is dependent on displacement, acceleration and rate of change of acceleration. Basically, these indices are function of the amplitude of vibration and frequency of vibration. In other words, the product of these values could be used as measure of comfort/discomfort.

However the sensation of smooth riding is also affected by other factors like temperature, humidity, noise, dust & various 98 psychological factors experienced by a passenger during run. The ride index is just a number with no units and its value gives us an indication of the riding comfort of a vehicle. The index is easily calculable during field trials by measuring the vertical/lateral accelerations using standard accelerometers.

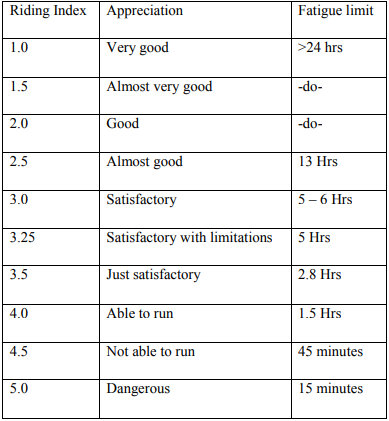

Ride Index gradations are as follows:

The ride index as described above gives the average riding quality of a vehicle over the chosen length of track (generally one kilometre). However, individual acceleration peaks also have an effect on the comfort of the passengers. Accordingly, limits for maximum acceleration values have also been laid down for coaches and locomotives. For details, the Third Criteria Committee Report of RDSO may be referred.

The Following Measures Should Be Given to Maintain Ride Index in ICF coach:-

Proper checking of primary suspension arrangement. Checking free height &height variation of primary suspension springs and grouping. Ensure sufficient level of oil in the telescopic hydraulic dash pot. Gap between safety loop & axle box lug should be within limit i.e. 40 mm. proper pairing of springs on secondary suspensions. Free height of spring should be within limit. Ensure proper working of shock absorber. Proper checking of side bearer for oil level & wear on bearing piece/plate should be within limit. Proper checking of silent bushes fitted in bolster for proper matching with centre pivot.

However the sensation of smooth riding is also affected by other factors like temperature, humidity, noise, dust & various 98 psychological factors experienced by a passenger during run. The ride index is just a number with no units and its value gives us an indication of the riding comfort of a vehicle. The index is easily calculable during field trials by measuring the vertical/lateral accelerations using standard accelerometers.

Ride Index gradations are as follows:

The Following Measures Should Be Given to Maintain Ride Index in ICF coach:-

Proper checking of primary suspension arrangement. Checking free height &height variation of primary suspension springs and grouping. Ensure sufficient level of oil in the telescopic hydraulic dash pot. Gap between safety loop & axle box lug should be within limit i.e. 40 mm. proper pairing of springs on secondary suspensions. Free height of spring should be within limit. Ensure proper working of shock absorber. Proper checking of side bearer for oil level & wear on bearing piece/plate should be within limit. Proper checking of silent bushes fitted in bolster for proper matching with centre pivot.

Proper checking of buffing gears for buffer face contact. Plunger stroke should not be more than 127 mm & less than 51 mm. All securing bolts & nuts should be properly fitted. Proper checking of draft gear. Coupling should be fully tightened evenly. Other securing nuts, washers, cotters should be in proper position. Anchor links should be intact with good silent block bushes. All break gear pins should be provided with proper bushes. Dynamo pulley & belt should not be loose. It should also be ensured that there is no wheel defect such as flat faces (not more than 50 mm), deep flange, skidded wheel, sharp flange, thin flange etc. In addition, the Ride Index can also be improved by ensuring proper p/way maintenance, signal defects & good engine man ship of the driver.

No comments:

Post a Comment